LED Display Soldering Iron Buying Guide

1. Product Overview

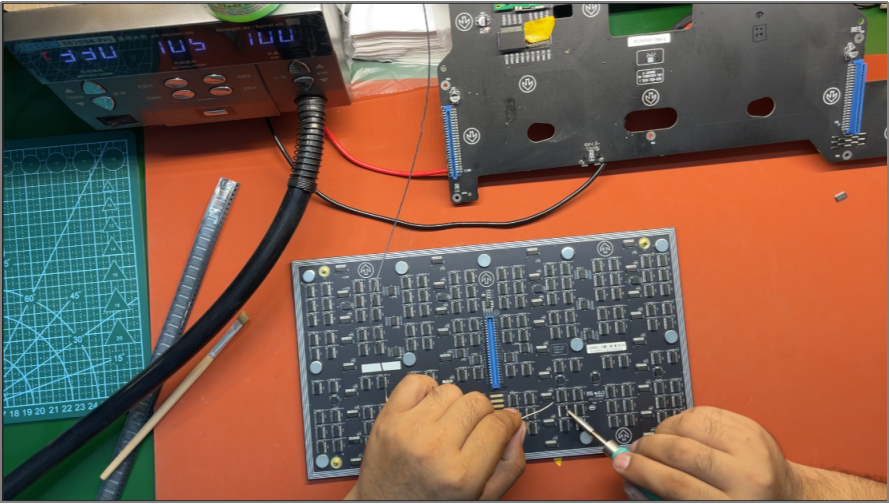

A soldering iron is a common precision tool in LED display repair, used for LED lamp replacement,cable re-soldering,

jumper wiring, and pad repair. It offers better point-to-point precision than a hot air gun and is typically used with

solder wire and flux. Common types include temperature-controlled and adjustable-temperature models.

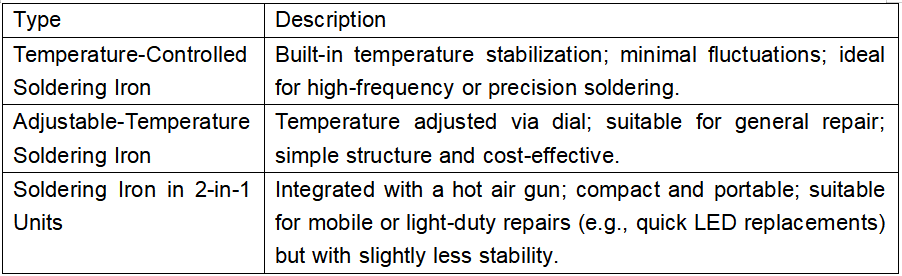

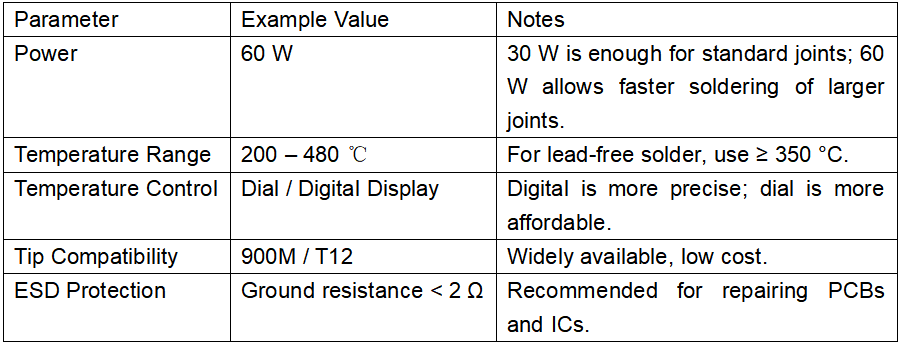

2. Types

3. Key Specifications

4. Applications

1)Soldering LED lamp pins (SMD1415, 2020, 2121, etc.)

2)IC pin repair (QFN, TSSOP packages)

3)Ribbon cable pin re-soldering

4)PCB jumper wiring for broken traces

5)Pad repair with pad repair tape

Recommended Accessories: solder wire (0.4 mm), flux, tip cleaning ball, soldering iron stand, ESD wrist strap, pad repair tape.

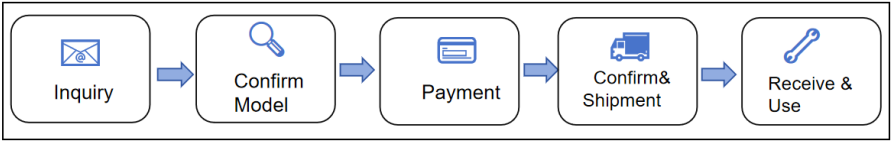

5. Selection Guide

Provide the following details when ordering:

· Power: e.g., 60 W for most LED joints; specify if different.

· Temperature Control: dial or digital display.

· Tip Type: 900M or T12 compatible.

· ESD Protection: required or not (< 2 Ω).

Example: For P2.5 indoor module repair — 60 W soldering iron, digital control, T12 compatible, ESD protected, qty: 2 units.

6. Usage Notes

1)Preheat for 30–60 s before use to stabilize temperature.

2)Clean or replace tips regularly to avoid cold joints.

3)Avoid prolonged high-temperature contact to prevent PCB damage.

4)Use ESD protection when working with sensitive components like driver ICs.

7. Any questions? Contact us: info@aoleled.com