LED Display Repair Hot Air Gun Buying Guide (Including 2-in-1 Models)

1. Product Overview

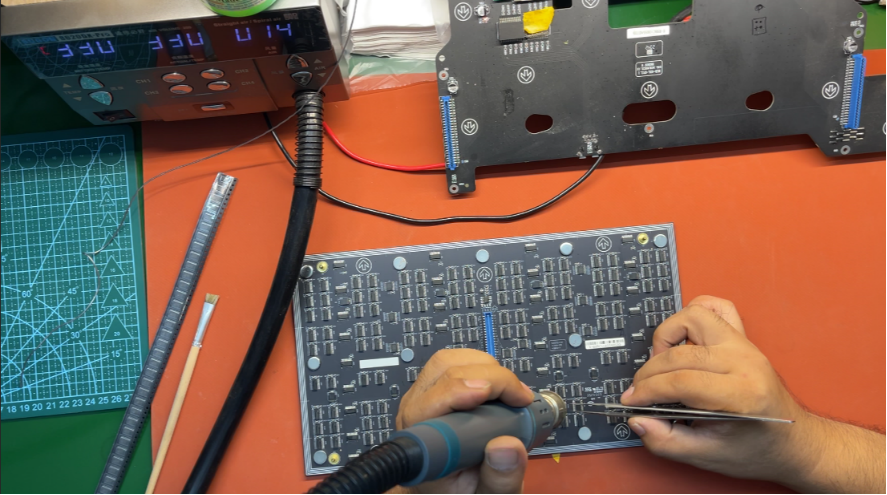

A hot air gun delivers controlled hot airflow to quickly heat local solder joints on LED displays, enabling non-destructive

removal of LEDs or ICs. Available in standalone and 2-in-1 models, chosen based on workload intensity.

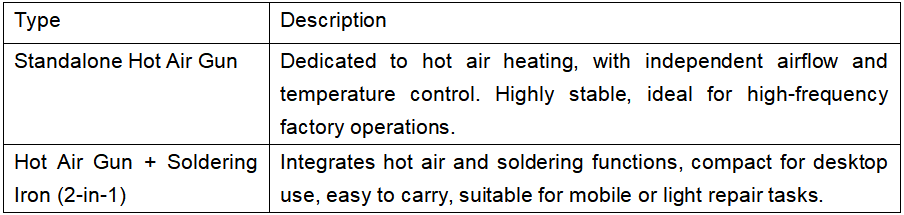

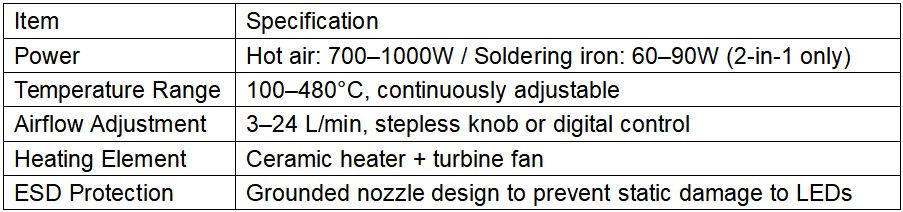

2. Hot Air Gun Types

3. Key Specifications

4. Applications

1) Removing SMD LEDs (e.g., SMD1515 / SMD2121 / SMD1921)

2) Replacing driver ICs (e.g., QFN / TSSOP packages)

3) Preheating and fixing lifted pads with copper foil

4) Repairing cold joints, dry joints, and localized preheating

Recommended Accessories: Solder paste, lead-free solder wire, pad repair tape, precision tweezers, ESD wrist strap

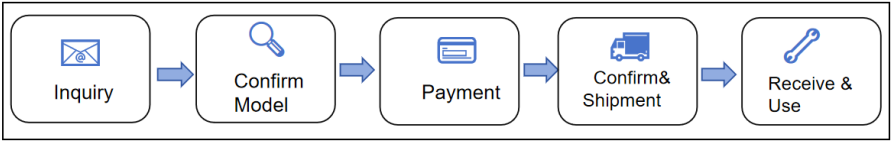

5. Ordering Guide

To confirm the correct model, please provide:

· Usage Frequency: Daily mobile repairs (2-in-1) / High-frequency factory repairs (standalone)

· Power Requirement: Standalone ≥900W, 2-in-1 ≥700W (hot air) + ≥60W (soldering iron)

· Temperature Control: Digital or knob control

Example: For daily mobile repairs, 2-in-1 hot air gun + soldering iron, digital temperature control, hot air ≥700W, 1 unit.

6. Safety & Usage Notes

1)Preheat for 30s before operation to avoid thermal shock

2)Keep nozzle 1–2 cm from PCB to prevent LED lens damage

3)Cool down for 30s before shutdown to prevent carbon buildup

4)Wear ESD wrist strap and heat-resistant gloves during operation

5)Regularly clean nozzle and check grounding for safety

7. Any questions? Contact us: info@aoleled.com