Ultra-Fine Insulated Wire for LED Display Repair

1. Product Overview

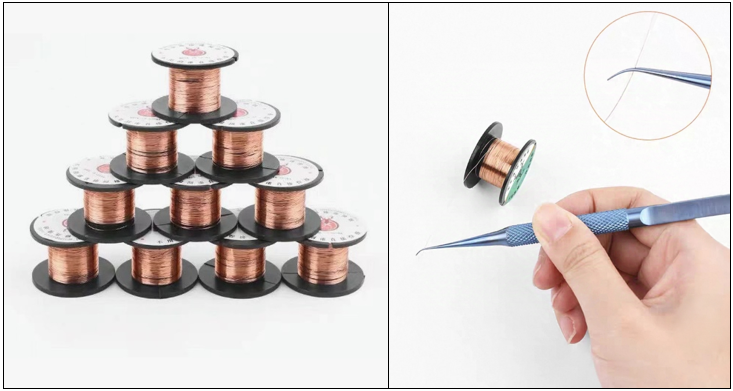

Ultra-fine insulated wire is a commonly used jumper wire in LED display repairs, suitable for pad restoration, chip re-wiring,

and signal connections in precision operations.

The conductor is made of flexible tinned or silver-plated copper wire, coated with a high-temperature-resistant insulating layer.

It offers excellent conductivity and heat resistance, resists peeling and carbonization, and is ideal for precise jumper soldering work.

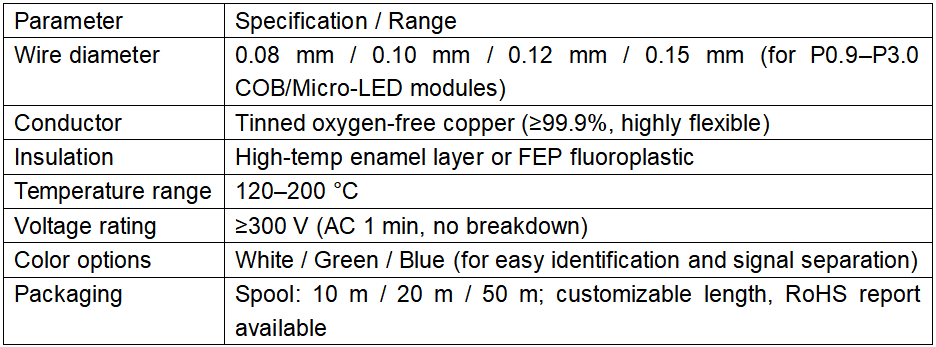

2. Product Specifications

3. Application Scenarios

1)Restoring pad connections after copper foil or pad damage (with solder pad repair tape)

2)Reconnecting broken or poorly soldered driver IC pins

3)Repairing damaged or loose ribbon cable signal lines by manual jump wiring

4)Signal or power line reinforcement in precision repairs to ensure long-term display stability

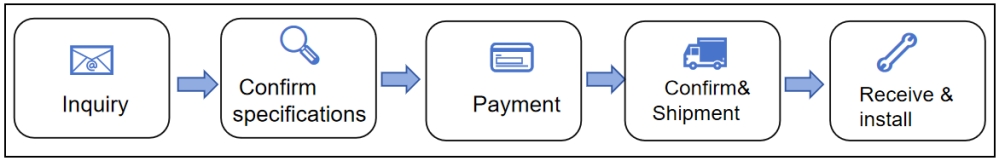

4. Ordering Guide

When placing an order, please provide:

-Wire diameter – e.g., 0.10 mm (general) or 0.08 mm (COB/Micro-LED)

-Color / insulation requirements – e.g., green FEP coating

-Length – 10 m / 20 m / 50 m or custom length

-Main application – LED pad repair, IC pin wiring, ribbon cable jumpers

-Certification – RoHS report required or not

Example: For indoor P2.5 module repair, 0.10 mm tinned OFC wire, green, 20 m, RoHS report required.

5. Usage Notes

1)Clean solder points before wiring to avoid cold solder joints or shorts

2)Keep wiring neat and firmly fixed, avoiding crossing or tangling

3)When passing through plastic housings or metal holes, ensure the insulation layer is abrasion-resistant to

prevent damage and short circuits

4)Store spools in a cool, dry place; avoid sharp bends to prevent deformation or insulation aging

6. Any questions? Contact us: info@aoleled.com