LED Display Solder Paste Buying Guide

1. Product Overview

Solder paste is a commonly used auxiliary material in LED display repair. It is typically used together with solder wire

to improve wetting, reduce oxidation, and ensure soldering quality. It is widely applied in LED replacement, IC soldering,

ribbon cable rework, and pad repair.

High-quality solder paste should offer strong fluxing activity, appropriate viscosity, low residue, noncorrosive performance,

and minimal spattering. Both no-clean and rosin-based options are available depending on the application needs.

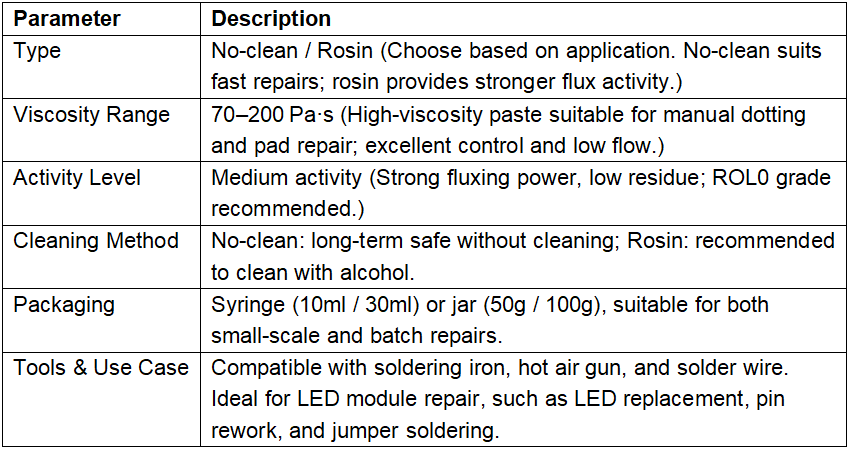

2. Key Specifications

3. Application Scenarios

Solder paste is used in the following typical LED display repair operations:

1)Enhances solder wetting and improves joint quality during LED replacement

2)Improves consistency when reworking ribbon cables and signal lines

3)Assists jumper wire soldering when used with pad repair tape

4)Boosts solder flow during precise manual operations, minimizing rework caused by oxidation

It is recommended to use together with solder wire, pad repair tape, and precision soldering tools to improve repair

efficiency and success rate.

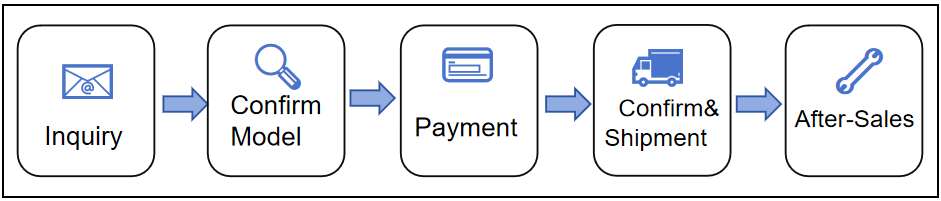

4. Ordering Guide

To help you select the right product, please provide the following:

Paste type: No-clean or Rosin (based on residue handling requirements)

Packaging: Syringe or Jar (for manual or batch use)

Estimated quantity: e.g. single-unit repair or bulk usage

Example: For indoor P2.5 module repair, no-clean solder paste, 1 × 100g jar

5.Usage Notes

1)Shake gently or press evenly before use to prevent separation

2)Do not overapply — excess residue may affect solder joint stability

3)If cleaning is needed, use anhydrous alcohol

6. Any questions? Contact us: info@aoleled.com