Solder Wire Buying Guide for LED Display Repair

1. Product Overview

Solder wire is a basic consumable commonly used in LED display repair, including LED lamp replacement and circuit maintenance.

High-quality solder wire ensures smooth soldering operations, improves joint quality, reduces rework rates, and enhances

overall repair reliability.

Solder wire used for LED display repair should offer fast wetting, good fluidity, solid solder joints, stable conductivity, low residue,low

smoke, and minimal spatter. Both leaded and lead-free formulations are available to meet environmental and process requirements.

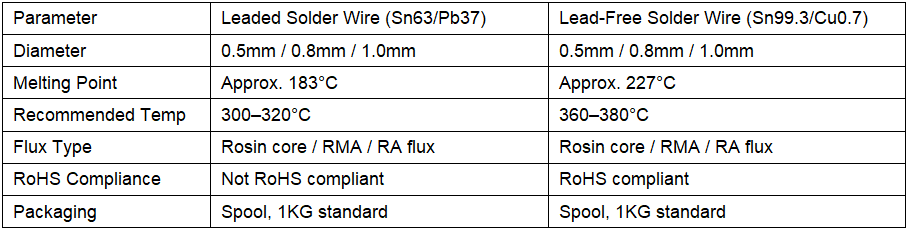

2. Product Specifications

3. Applications & Common Issues Solved

1)Solder wire is suitable for the following LED display repair scenarios:

2) Replacing dead LEDs, ICs, or other driver chips

3) Fixing loose signal connectors, and replacing or re-soldering resistors and capacitors

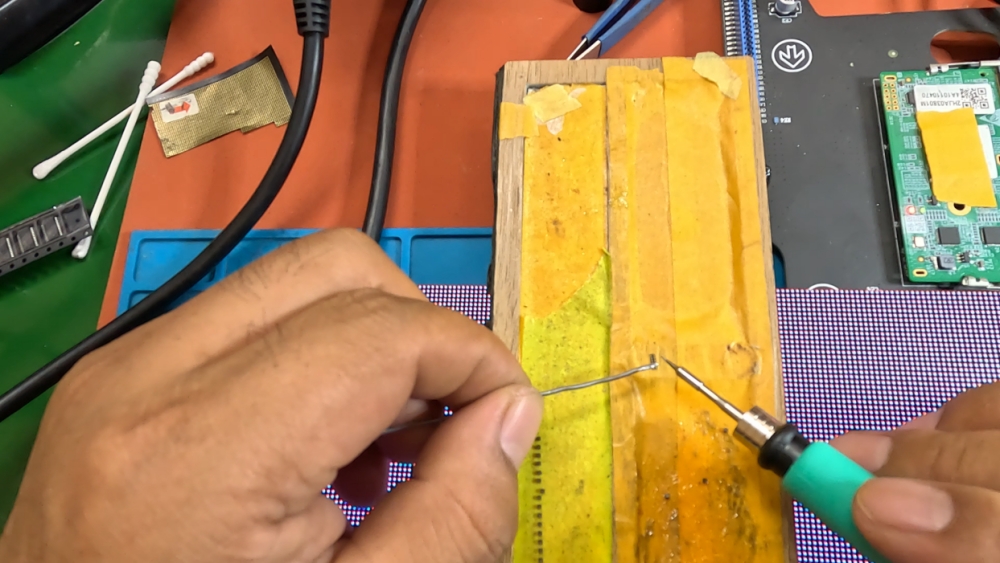

4) Restoring damaged pads using solder pad paper

5) Resolving signal interruptions, unstable power, and other circuit issues through re-soldering

Choosing the right solder wire can effectively prevent cold solder joints, shorts, weak connections, and other common failures,

improving overall repair success rates.

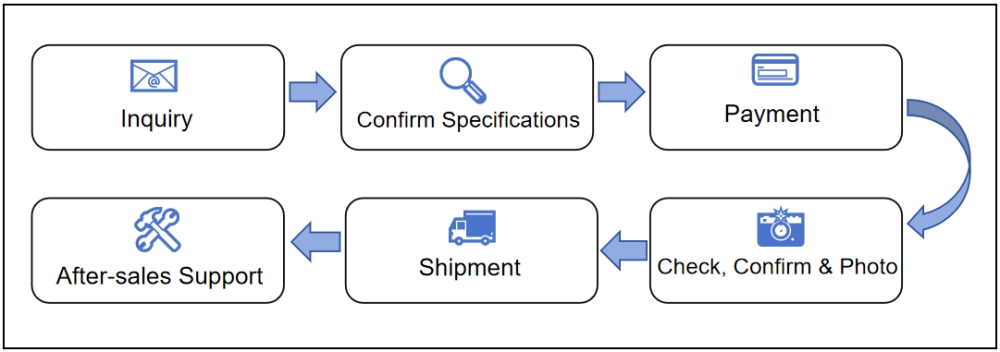

4. Required Information for Ordering

To place an order, simply let us know:

· Solder type: Leaded or lead-free

· Quantity needed: (e.g., 10 rolls)

5. Usage Notes

To ensure soldering quality and operational safety, please observe the following:

1) Work in a well-ventilated area to avoid prolonged fume exposure

2) Control soldering temperature to prevent burning the flux or damaging soldering iron tips due to overheating

3) Store solder wire properly after use to avoid moisture and oxidation

4) Personal protective equipment is recommended during extended use

6. Any questions? Contact us: info@aoleled.com