LED Display Solder Pad Paper Selection Guide

1. Product Overview

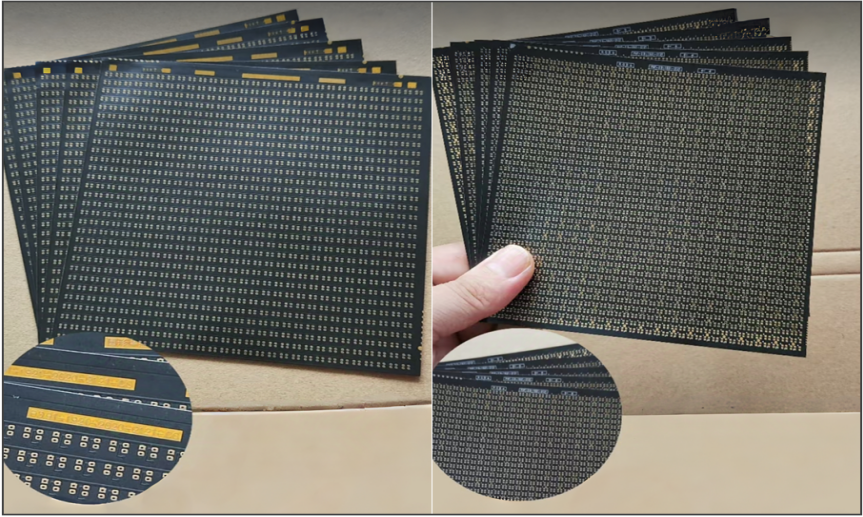

During installation, removal, or transport of LED displays, PCB solder pads may detach due to impact or bending.

Solder pad paper is used to restore these damaged areas.

It is a key consumable for repairing LED modules and SMD lamps, featuring high temperature resistance,

anti-static properties, and precise LED positioning.

Widely used in SMD repairs, module refurbishment, and routine maintenance, it is essential for professional

LED display servicing.

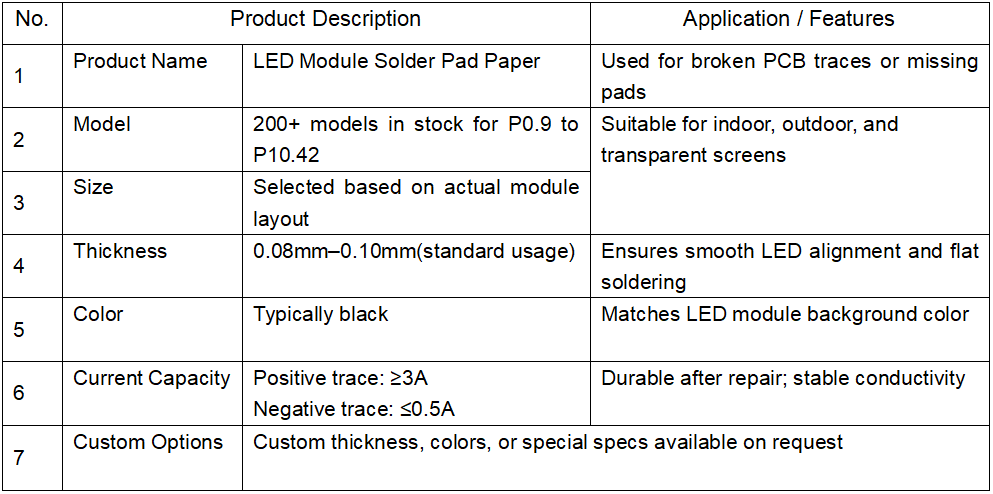

2. Product Specifications

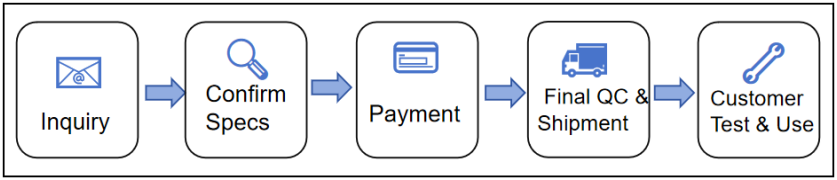

3.Ordering Guide & Process

Please provide the following information to match the correct solder pad paper:

Module pixel pitch (accurate to 3 decimal places,For example: P1.5625 should be noted as P1.562

— not P1.5 — to ensure accurate matching.)

LED lamp specification (e.g., 1010, 1515)

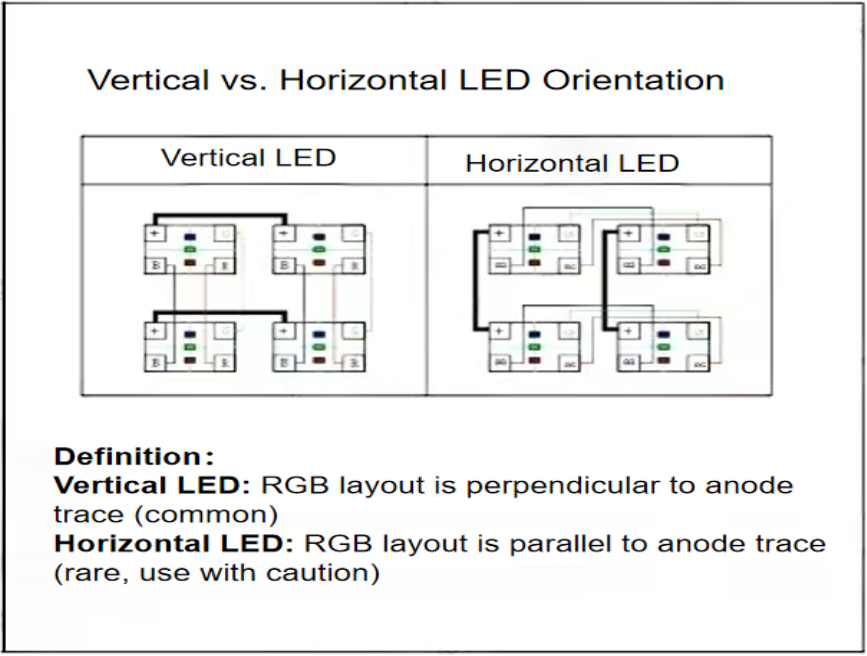

LED orientation: vertical or horizontal

Clear photos of the front and back of the module

Quantity needed

Example: P1.5625, 1010, vertical orientation, 5 pcs needed.

(Please attach module photos for accurate confirmation.)

MOQ: 1PCS

4. Usage Notes

1)Clean the pad area thoroughly before soldering to remove oxidation or solder residue.

2)Make sure the pad layout matches the LED spacing to avoid misalignment.

3)Do not reuse the same pad paper to prevent heat conduction failure.

4)Store in a dry environment to maintain insulation quality.

5. Repair Video Reference

Watch our LED solder pad replacement video on YouTube:

Difficult? How to Replace a P1.2 Solder Pad?

6. Any questions?Contact us: info@aoleled.com